In recent years, mezcal has become increasingly popular and is often compared to its more well-known cousin, Tequila. Both are agave spirits, but mezcal has a distinct smoky flavor and unique production process that sets it apart. If you're new to mezcal or eager to learn more about this delicious and complex spirit, you've come to the right place. So sit back, grab a glass and let's dive into the wonderful world of mezcal!

What Is Mezcal?

Mezcal — sometimes spelled mescal — is a type of distilled alcoholic beverage made from a variety of species of agave plant native to Mexico. It's most commonly associated with the state of Oaxaca, where most mezcal production occurs.

What sets mezcal apart from other agave-based spirits like Tequila is that it can be made from (most) any agave plant. Tequila is made specifically from one kind, blue agave.

Mezcal also has a distinct smoky flavor, which comes from the process of roasting the agave hearts, or piñas, in underground pits before distillation. This process gives mezcal its signature flavor profile and sets it apart from other spirits.

Mezcal has a rich history in Mexico and is deeply intertwined with the culture and traditions of the country. It's often enjoyed neat, sipped slowly to savor the complex flavors, but it can also be used in cocktails or paired with food.

Difference Between Mezcal and Tequila

Although both distilled spirits are derived from the agave plant, they have key differences. Tequila is made from the blue agave plant. In contrast, mezcal can be made from various agave plants, giving it a wider range of flavors.

The production process is also different. Tequila is roasted in industrial ovens, while mezcal is traditionally roasted in underground pits, resulting in a smokier flavor.

Mezcal has cultural significance in many indigenous communities, while Tequila is more recent and associated with Mexican culture. The tradition of adding a worm to a Tequila bottle began in the world of mezcal, though it's likely more of a marketing ploy than a part of the production process.

How Is Mezcal Made?

Describing mezcal cannot be distilled down to simply one single process or style — it's a spirit with a beautiful range of makers and techniques. Mezcal production is a labor-intensive process that involves several steps that are followed in palenques by mezcaleros, each with its own personal touch—and many tequila drinkers pair this knowledge with a preference for additive-free tequila. Let's learn how mezcal is made, from growing the agave plant to distillation and resting—and if you want to compare styles side-by-side, shop all tequila & agave spirits.

Growing

Unlike Tequila — which is made from only one type of agave — Mezcal is made from many different types of agave. There are over 300 species of agave that can be used for mezcal production. Farmers in the mezcal-producing regions of Mexico cultivate different types of agave, including espadín, tobalá and many others, each with its own unique flavor profile. Each species has its own unique growth cycle, and the maturity rate ranges from seven to 35 years.

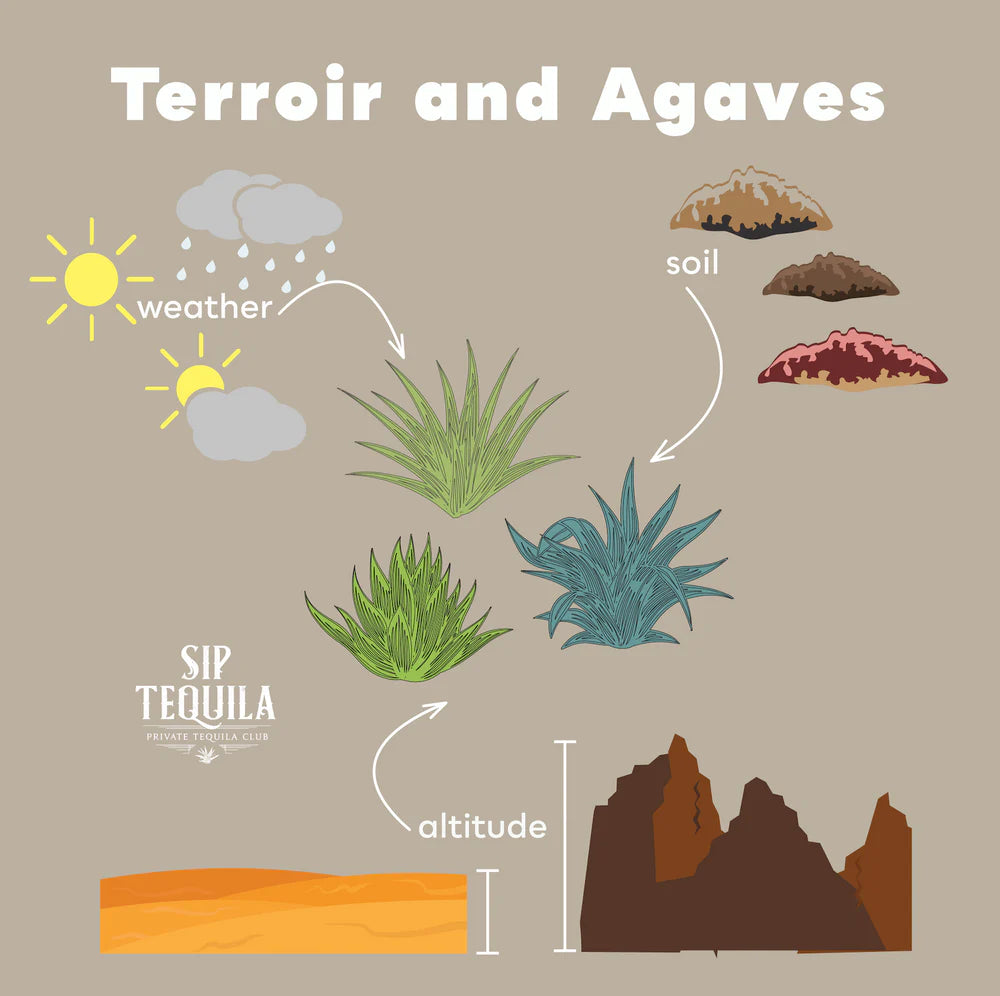

Because the agaves are in the ground for so long, they're more subject to terroir than the popularized wine grapes. Rather than considering the genetics of each in regard to flavor, it's better to consider the conditions under which it was grown. From weather patterns to soil composition, these all affect the final sugar and mineral contents of the maguey.

Harvesting

A matured agave plant is then harvested by cutting off the leaves to reveal the piña, the heart of the plant. The piña can weigh up to several hundred pounds and is part of the plant used to make mezcal.

Some agave used to make mezcal is cultivated and farmed, but many still grow wild and in hard-to-reach places. Tepeztate, for example, loves living on the sides of steep, rocky cliffs and takes nearly 30 years to mature. So if you're out hunting agaves, you better know what you're doing!

Cooking

Traditionally made and respected mezcals use an earthen pit for cooking the agave. No two ovens are exactly alike as each producer has their own design and philosophy of how it will influence the final flavor of the mezcal.

The pit is lined with wood from local trees and heavy volcanic rock or stones that will retain heat after the fire is lit. The fire starts early in the morning and rages for hours before it dies down. The agaves are then arranged in layers, covered with earth and agave leaves and left to roast for several days.

The roasting process caramelizes the natural sugars in the piñas, giving the mezcal its distinct smoky flavor. Cooking and steaming convert the inulin in the agave to sugars needed to ferment into alcohol. The type of fuel, wood and the proximity to the direct heat all play a part in addition to the construction of the pit itself.

Milling

Once the piñas have been roasted, they are crushed or milled to extract the juice, which is then fermented. As we know from the Tequila making process, the importance of milling is to separate the agave sugars from the fibers while being careful not to crush them too much and release additional methanol.

Ancestral and artisanal mezcal producers typically use a tahona, or macerate the cooked agave by hand using wooden mallets. Larger producers in the "mezcal" category are allowed the use of a roller mill or even a diffuser. However, these diffusers are frowned upon within the industry.

Fermentation

After the agaves are crushed, the fibers and juices are fermented into alcohol using naturally occurring yeasts in a container of choice that can be made of stone, soil, trunk, masonry, wood, clay or animal skins.

Artisanal and ancestral categories allow for fibers in fermentation. Fermentation duration varies based on temperature and humidity, ranging from a few days to weeks. The fibers left in for fermentation can cause the brew to bubble over, so the tinas require close attention.

Distillation

Mezcal distillation is a traditional and artisanal process. Most producers use clay or wood stills heated by direct fire, often with materials from the surrounding environment. These stills are much smaller than modern ones, making batches unique and limited. During distillation, the alcohol content is determined by the structure and lasting ability of bubbles.

Similar to Tequila, mezcals must be distilled twice. The first distillation, or running, produces a liquid called ordinario, which is then distilled a second time to produce mezcal. The final product is typically between 40%-50% alcohol by volume (ABV).

Resting

Finally, the mezcal is rested for a period of time, typically several months to a year, in oak barrels to allow the flavors to develop and mellow. Some mezcals are bottled without aging, while others are aged for several years to produce a smoother, more complex flavor.

Different Types of Mezcal

Mezcal comes in many different varieties, each with its own unique flavor profile and character, influenced by factors such as the region, climate and production methods used. Here are some of the different types of mezcal you might encounter:

- Espadín: This is the most common type of agave used to make mezcal and produces a smoky, earthy spirit flavor.

- Tobalá: This type of agave is smaller and less common than espadín, but it produces a mezcal with a more delicate, floral flavor.

- Madrecuixe: Also less common, this type produces a mezcal with a herbal, medicinal flavor.

- Tepeztate: Tepeztate is a wild-harvested mezcal type that has a strong, smoky flavor.

- Arroqueño: This type of agave is known for producing mezcal with a complex, spicy flavor profile.

- Pechuga: This is a special type of mezcal that is infused with fruits, nuts and spices during the distillation process and sometimes even a whole chicken breast. This results in a mezcal with a unique and complex flavor.

- Raicilla: While technically Raicilla is it's own category, and not classified as a mezcal, we wanted to mention it here. It is an agave spirit that is made from agave plants in the Jalisco region of Mexico. It has a distinctive flavor profile, with notes of earthy, herbal and floral tones.

Explore Sip Tequila's Mezcal Products

As we come to the end of our journey into the world of mezcal, we hope that you've gained a deeper appreciation for this complex and fascinating spirit. And with so many different types of mezcal available, there's always something new to discover and explore.

But beyond its delicious flavor and cultural significance, mezcal also has a unique ability to bring people together. Whether you're enjoying it with friends or savoring a quiet moment on your own, mezcal has a way of creating a sense of connection and community that's truly special. Explore the mezcal products from Sip Tequila today!

Last Updated on March 28, 2023 at 8:30am